-

2021/08/23

2021/08/23A safe distance from including the electrical clearance (distance), creepage distance (creepage distance) and insulat...

-

2021/08/23

2021/08/231, FR – 4 sheet is a kind of epoxy plate, has high mechanical properties and dielectric properties, good heat r...

-

2021/08/23

2021/08/23North American car market is leading the global networking, PCBA OEM generation material predicts 2025, American domi...

-

2021/08/23

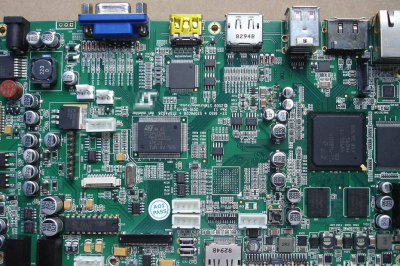

2021/08/231, brush paint anti-corrosion protection must be tested before the PCBA assembly, inspection, and after a thorough cl...

Anti-corrosion coating PCBA paint what technical requirements?

Release time:2021/08/23 news viewed:558

1, brush paint anti-corrosion protection must be tested before the PCBA assembly, inspection, and after a thorough clean.

2, use the brush to clean, banned again for other assignments; Brush paint to be careful not to drip does not need to paint the parts; After using the brush to wash clean with thinner and so on.

3, coating layer should be transparent and uniform PCB and components, colour and lustre and consistency uniform.

4, process steps as follows: besmear to brush A face – > table dry to besmear brushs surface B, room temperature curing

5, coating thickness, coating thickness of 0.1 mm to 0.3 mm (dry film thickness is commonly 30-100 um)

Six, all coating operation should be not less than 16 ℃ and below 75% relative humidity conditions. PCB as a composite material absorption of moisture, such as not to tide, anti-corrosion paint is not fully protective, and dried by vacuum drying can remove most of the moisture.

- Do you really understand PCB? Take you to ...

- Collect now! A useful PCB final checklist!

- PCB circuit board factory wastewater treat...

- PCBA board between the shell and safety re...

- [Technology] PCB surface treatment process

- PCB industry pattern and development trend

- What are the benefits of using precious me...

- What are the commonly used types of PCBA b...