-

2021/08/23

2021/08/23A safe distance from including the electrical clearance (distance), creepage distance (creepage distance) and insulat...

-

2021/08/23

2021/08/231, FR – 4 sheet is a kind of epoxy plate, has high mechanical properties and dielectric properties, good heat r...

-

2021/08/23

2021/08/23North American car market is leading the global networking, PCBA OEM generation material predicts 2025, American domi...

-

2021/08/23

2021/08/231, brush paint anti-corrosion protection must be tested before the PCBA assembly, inspection, and after a thorough cl...

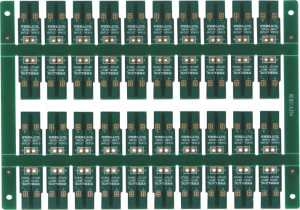

Do you really understand PCB? Take you to unlock the secrets on the PCB board!

Release time:2018/08/08 news viewed:848

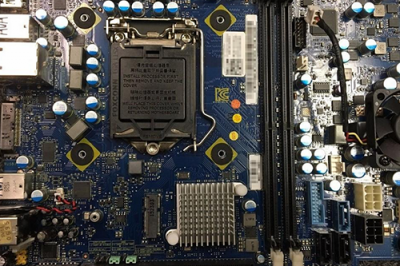

Why use different colors for the solder mask?

Many DIY players will find that the variety of PCB products used in the market is varied in color and dazzling. The more common PCB colors are black, green, blue, yellow, purple, red, and brown. Some manufacturers have also developed PCBs of different colors such as white and pink.

In the traditional impression, the black PCB seems to be positioned at the high end, while the red, yellow, etc. are low-end dedicated. Is that the case?

We know that both sides of the PCB are copper layers. In the production of PCBs, the copper layer is manufactured by addition or subtraction, and finally a smooth and unprotected surface is obtained. Although the chemical properties of copper are not as active as aluminum, iron, magnesium, etc., in the presence of water, pure copper and oxygen are easily oxidized; because of the presence of oxygen and water vapor in the air, the surface of pure copper is in contact with air. The oxidation reaction will occur soon. Since the thickness of the copper layer in the PCB is very thin, the oxidized copper will become a poor conductor of electricity, which will greatly impair the electrical performance of the entire PCB.

In order to prevent copper oxidation, and to separate the soldered and non-welded parts of the PCB during soldering, and to protect the surface of the PCB, engineers invented a special coating. This coating can be easily applied to the surface of the PCB to form a protective layer with a certain thickness and to block copper and air contact. This layer of coating is called a solder mask and the material used is a solder resist.

Since it is called lacquer, it must have a different color. Yes, the original solder resist can be made colorless and transparent, but the PCB often needs to print small text on the board for maintenance and manufacturing convenience. The transparent solder resist can only reveal the background color of the PCB, so that the appearance is not good enough whether it is manufactured, repaired or sold. So engineers added a variety of colors to the solder resist, and finally formed a black or red, blue PCB.

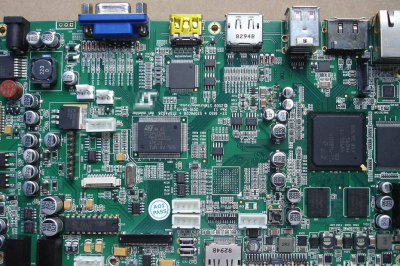

Black PCB is difficult to see the trace, which brings difficulties for maintenance

From this point of view, the color of the PCB has nothing to do with the quality of the PCB. The difference between a black PCB and a blue PCB, a yellow PCB, and other color PCBs is that the color of the solder resist on the final brush is different. If the PCB design and manufacturing process are almost the same, the color will not have any effect on the performance and will not have any effect on the heat dissipation. Regarding the black PCB, since the surface traces are almost completely covered, it causes great difficulty in the later maintenance, so it is a color that is not convenient to manufacture and use. Therefore, in recent years, people have gradually reformed, abandoned the use of black solder resist paint, and turned to use dark green, dark brown, dark blue and other solder resist paint to facilitate manufacturing and maintenance.

Having said that, everyone has basically understood the problem of PCB color. The reason why “colors represent high-end or low-end” is that manufacturers prefer to use black PCBs to make high-end products, which are caused by red, blue, green, yellow, etc. To sum up one sentence: the product gives the meaning of the color, not the color gives the meaning of the product.

- What are the commonly used types of PCBA b...

- Anti-corrosion coating PCBA paint what tec...

- [Technology] PCB surface treatment process

- What are the benefits of using precious me...

- PCB circuit board factory wastewater treat...

- What are the benefits of using precious me...

- PCBA board between the shell and safety re...

- Collect now! A useful PCB final checklist!