-

2021/08/23

2021/08/23A safe distance from including the electrical clearance (distance), creepage distance (creepage distance) and insulat...

-

2021/08/23

2021/08/231, FR – 4 sheet is a kind of epoxy plate, has high mechanical properties and dielectric properties, good heat r...

-

2021/08/23

2021/08/23North American car market is leading the global networking, PCBA OEM generation material predicts 2025, American domi...

-

2021/08/23

2021/08/231, brush paint anti-corrosion protection must be tested before the PCBA assembly, inspection, and after a thorough cl...

What are the benefits of using precious metals such as gold and silver on the PCB?

Release time:2018/08/09 news viewed:872

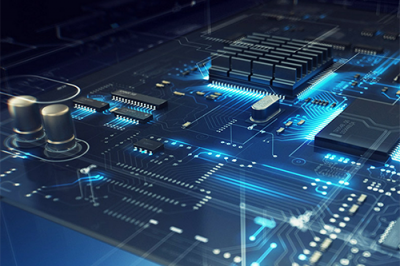

The color is clear, let’s talk about the precious metals on the PCB! When some manufacturers promote their products, they will especially mention that their products use special processes such as gold plating and silver plating. So what is the use of this process?

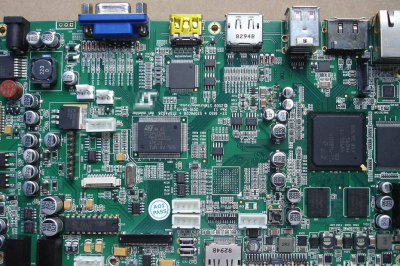

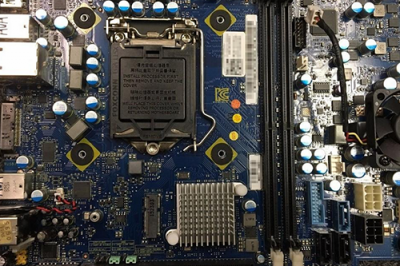

The PCB surface requires soldering components, requiring a portion of the copper layer to be exposed for soldering. These exposed copper layers are called pads, and the pads are generally rectangular or circular with a small area. In the above, we know that the copper used in the PCB is easily oxidized, so after the solder resist is applied, the only copper exposed on the pad is exposed to the air. If the copper on the pad is oxidized, it is not only difficult to solder, but also the resistivity is greatly increased, which seriously affects the performance of the final product. So, engineers came up with a variety of ways to protect the pads. For example, it is plated with inert metal gold, or a layer of silver is chemically coated on the surface, or a special chemical film is used to cover the copper layer to prevent contact between the pad and the air.

The exposed pad on the PCB, the copper layer is directly exposed

This part needs protection to prevent it from being oxidized

From this perspective, whether it is gold or silver, the purpose of the process itself is to prevent oxidation and protect the pads, so that they can ensure yield in the next welding process. However, the use of different metals will require storage and storage conditions for the PCBs used in the production plant. Therefore, the PCB factory generally completes the PCB production and uses the vacuum plastic packaging machine to package the PCB before delivery to the customer to ensure that the PCB does not suffer from oxidative damage. Before the last component is soldered on the machine, the board manufacturer also needs to check the oxidation degree of the PCB and remove the oxidized PCB to ensure the yield. The card that the end consumer got is already tested. Even after long-term use, the oxidation will almost only occur at the plugging and connecting parts, and it has no effect on the pads and the components that have been soldered.

Since the resistance of silver and gold is lower, will the heat generation of the PCB be reduced after using special metals such as silver and gold?

We know that the biggest factor affecting calorific value is resistance. The resistance is related to the material of the conductor itself, the cross-sectional area and length of the conductor. The thickness of the metal surface of the pad surface is even much lower than 0.01 mm. If the pad is processed by OST (Organic Protective Film), there is no excess thickness at all. The resistance shown by such a small thickness is almost equal to 0, and even cannot be calculated, of course, it does not affect the amount of heat generated.

In the previous: PCB circuit board factory wastewater treatment

The next article: Do you really understand PCB? Take you to unlock the secrets on the PCB board!

- PCB circuit board factory wastewater treat...

- PCB industry pattern and development trend

- Do you really understand PCB? Take you to ...

- [Technology] PCB surface treatment process

- Collect now! A useful PCB final checklist!

- What are the benefits of using precious me...

- Anti-corrosion coating PCBA paint what tec...

- About PCBA OEM generation interconnection ...